Honorable purpose drives powerful work.

I value integrity, effort and passion above all else. If you do too, let's roll up our sleeves, rack our brains and solve something amazing. I'm always looking for new challenges and opportunities to grow as a person and as an engineer.

Featured Work

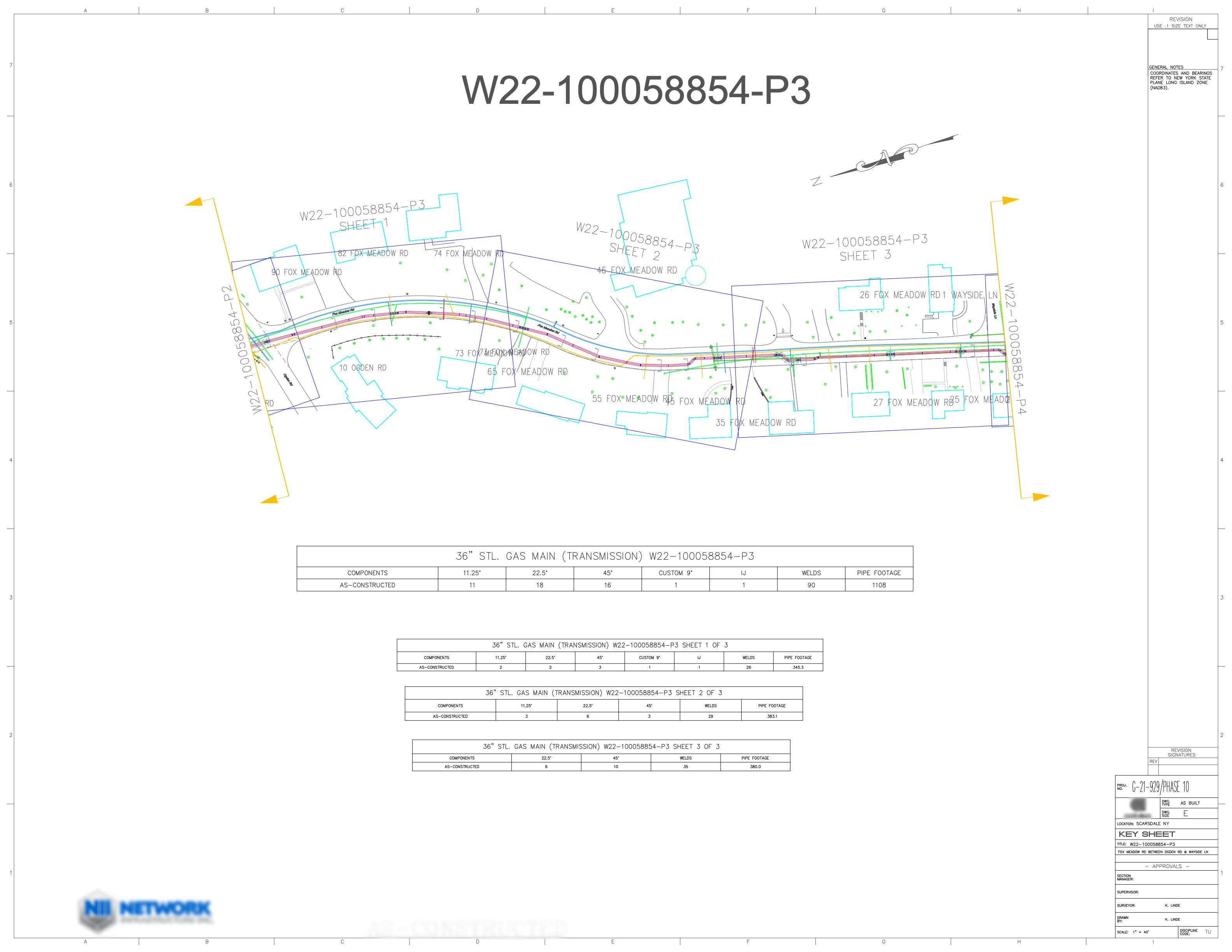

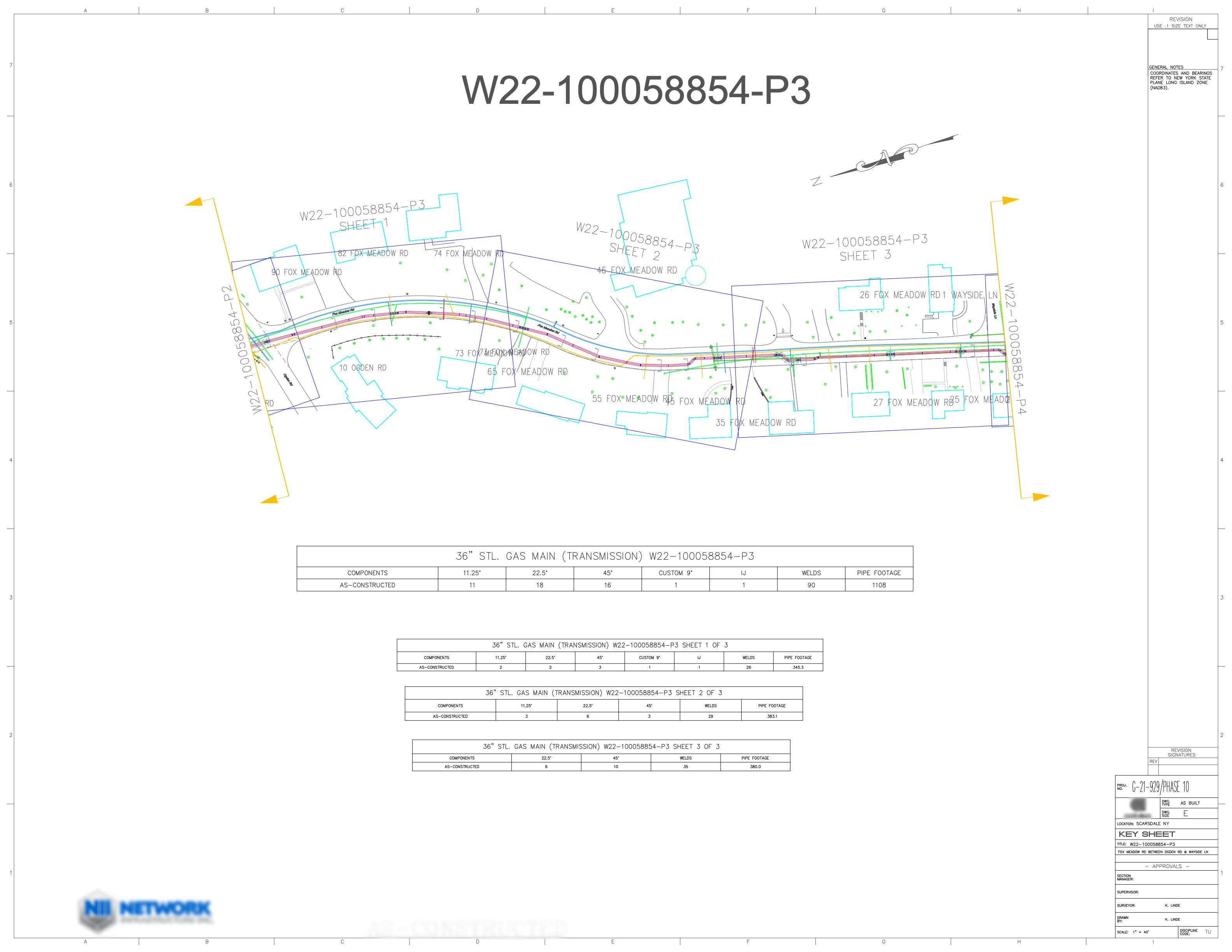

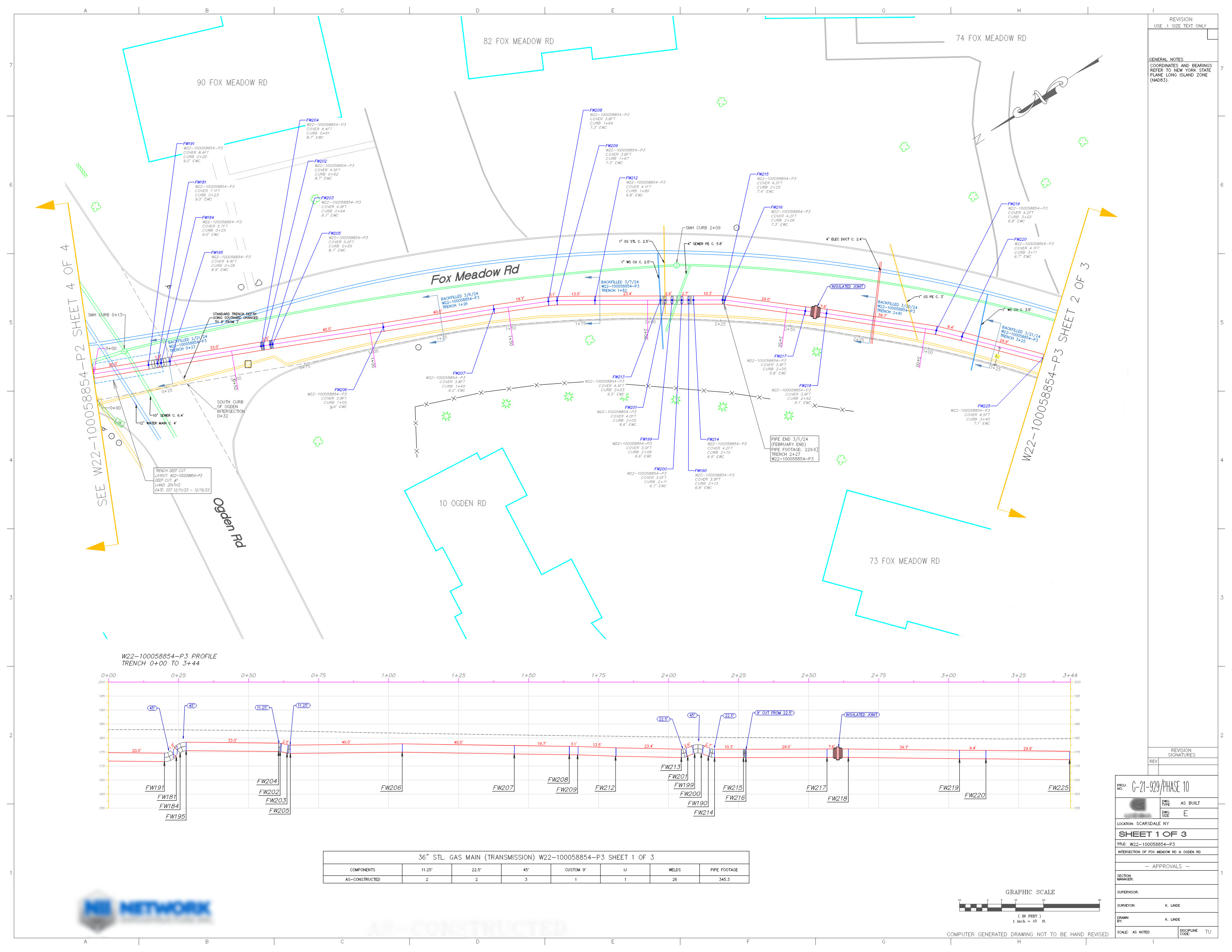

AutoCAD Civil 3D

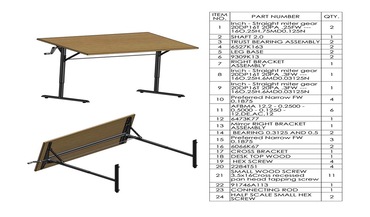

Adjustable Drafting Desk

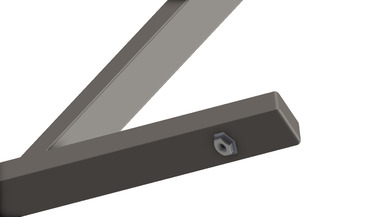

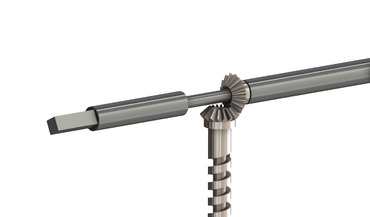

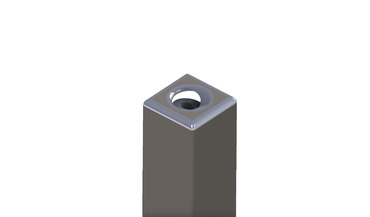

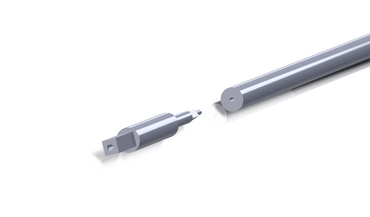

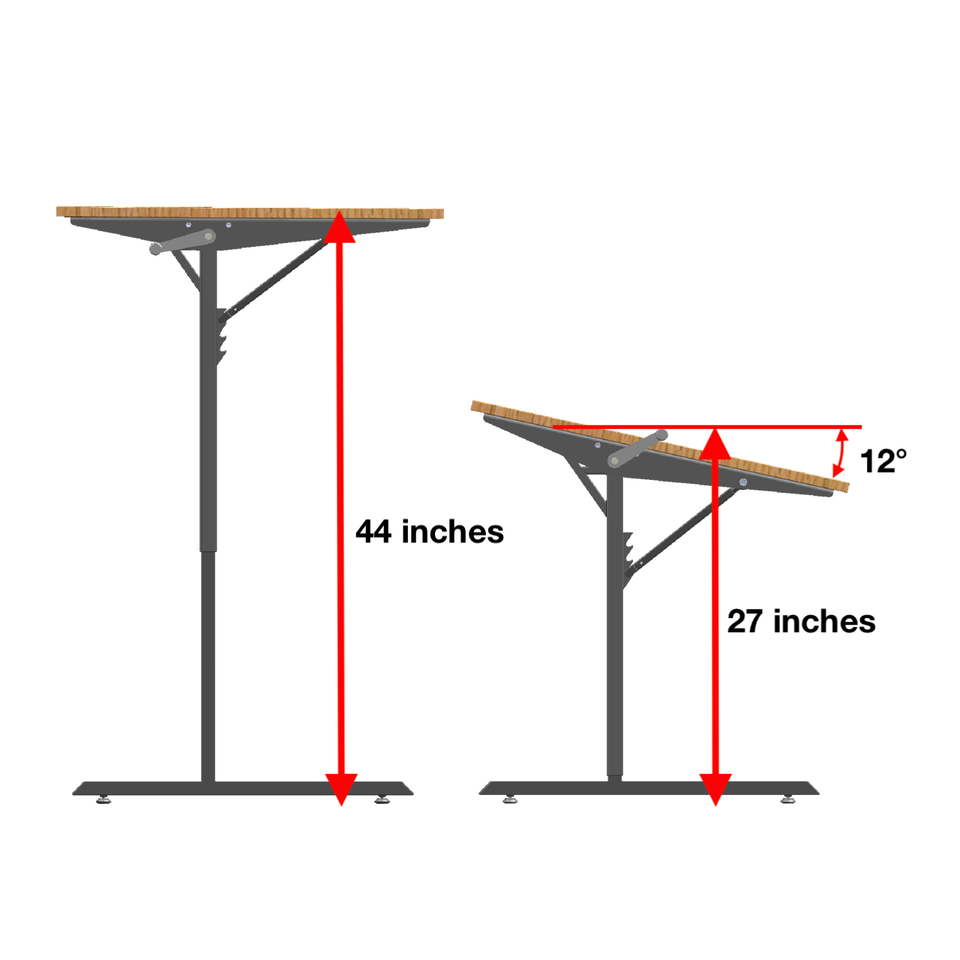

This is a side-project of my own that had begun when my back and legs ached sitting long hours leading

me on an internet search to see if an adjustable standing desk that tilts existed. To my surprise, there

were no such product on the market, so I designed one myself in SolidWorks with manufacturability and

affordability a priority. I created a desk that can go from a height of 44 inches down to 27 and go from

being level to 6 or 12 degrees of tilt. One rotation of the handle adjusts the height a finely tunable

3/8 inch. Inside both legs of the desk are miter gears translating the torque from the crank handle to

helical screws. The threads of the helical screw create the lifting force to raise the desk by pushing

against female threads anchored in the leg bases.

This is a side-project of my own that had begun when my back and legs ached sitting long hours leading

me on an internet search to see if an adjustable standing desk that tilts existed. To my surprise, there

were no such product on the market, so I designed one myself in SolidWorks with manufacturability and

affordability a priority. I created a desk that can go from a height of 44 inches down to 27 and go from

being level to 6 or 12 degrees of tilt. One rotation of the handle adjusts the height a finely tunable

3/8 inch. Inside both legs of the desk are miter gears translating the torque from the crank handle to

helical screws. The threads of the helical screw create the lifting force to raise the desk by pushing

against female threads anchored in the leg bases.

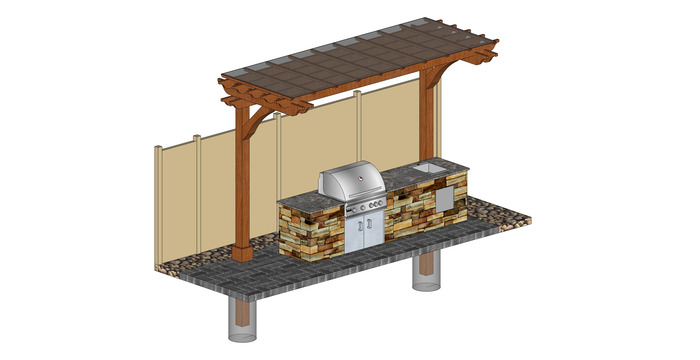

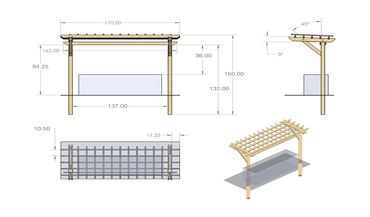

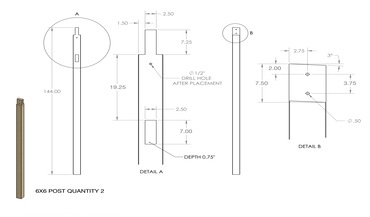

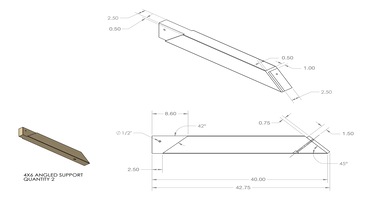

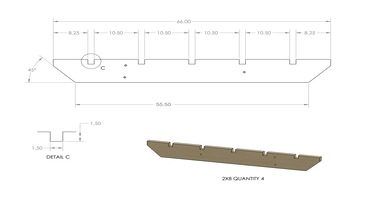

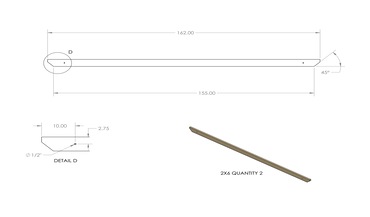

Cantilever Trellis Pergola

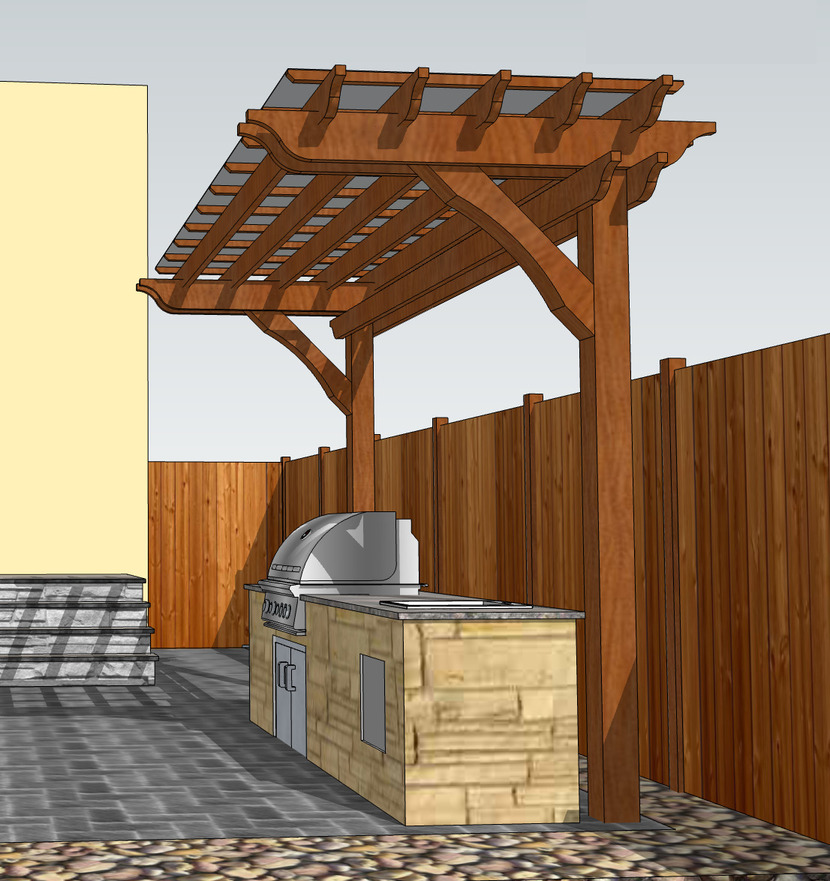

Following the completion of my uncle's outdoor kitchen him and I build, we agreed something was needed

to protect it from the elements while being aesthetically pleasing. Not wanting to overwhelm the patio

with a traditional 4-post pergola, I proposed a cantilevered trellis structure that admirably accents

his Tudor home. This cantilever pergola maintains an open feeling yet provides a sense of intimacy and

privacy where it's needed. Several engineering solutions were incorporated to facilitate the

cantilever,

thereby keeping the patio free from vertical support posts while maintaining a safe stucture for years

to come. Construction of this project is planned to begin in spring 23'.

Following the completion of my uncle's outdoor kitchen him and I build, we agreed something was needed

to protect it from the elements while being aesthetically pleasing. Not wanting to overwhelm the patio

with a traditional 4-post pergola, I proposed a cantilevered trellis structure that admirably accents

his Tudor home. This cantilever pergola maintains an open feeling yet provides a sense of intimacy and

privacy where it's needed. Several engineering solutions were incorporated to facilitate the

cantilever,

thereby keeping the patio free from vertical support posts while maintaining a safe stucture for years

to come. Construction of this project is planned to begin in spring 23'.

Finite Element Analysis

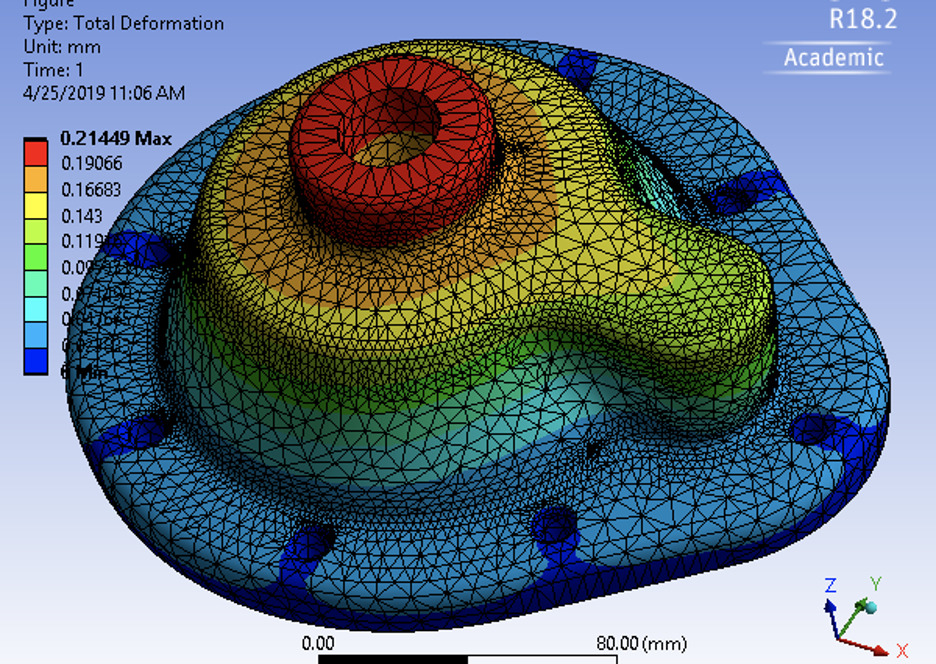

Aluminum Pump Housing Deformation

This ANSYS simulation involved a thermal stress analysis on a pump housing. The housing had a fixed support on its bottom mating surface and frictionless supports on the surrounding countersink holes. The exterior surface was exposed to convention of 20°C. The inner surface was set to a constant 90°C while the bottom mating surface was set to a constant 60°C. The greatest equivalent stress occurred at the frictionless countersink holes while the greatest deformation occurred near the top exit hole. The factor of safety for the aluminum pump housing was a maximum of 15 and a minimum of 0.47 indicating the part needed further optimization.

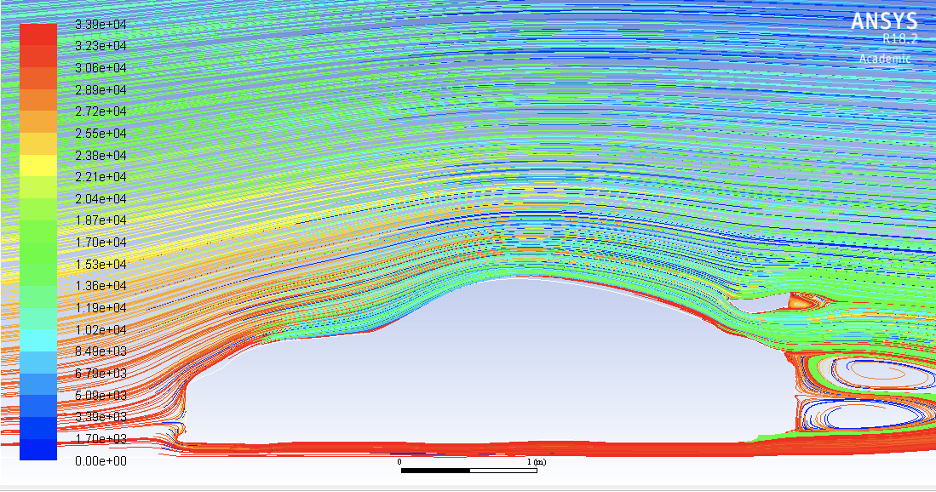

Determination of Drag from CFD Analysis

This computational fluid dynamics analysis determined the drag coefficient of a Porsche GT2 RS model imported from SolidWorks. The car model and flow region were meshed and resulted in a 0.34 drag coefficient—accurate to what Porsche reports for this performance car. The figure illustrates the velocity streamlines around the car with aerodynamic flow separation at the trailing edge of the car and the boundary layer formed over the body.

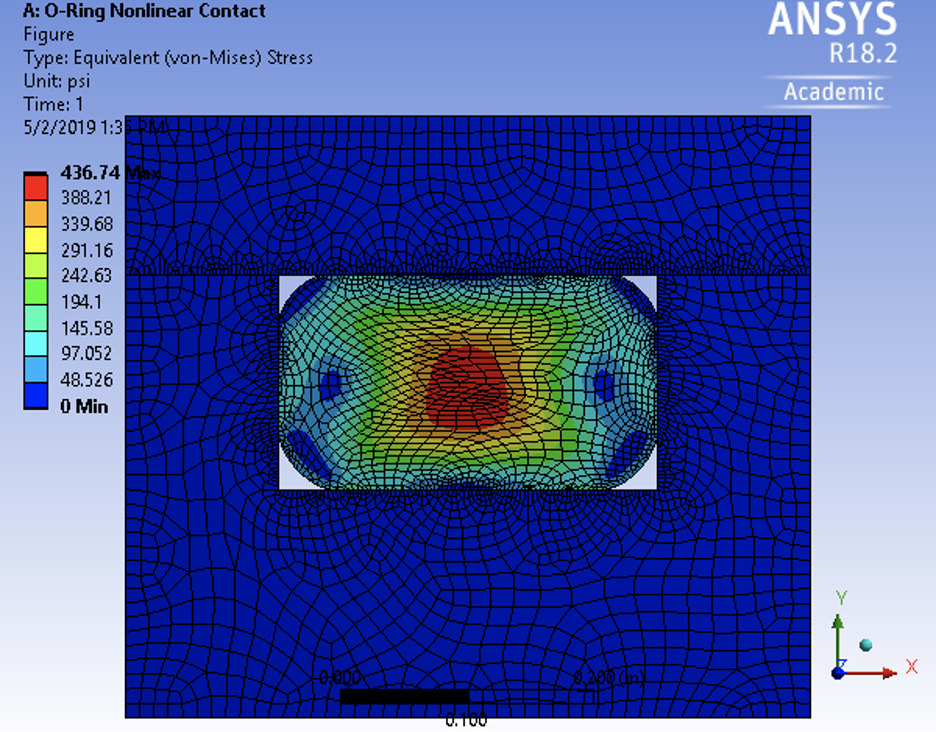

Non-linear Contact of O-Ring Seal

This simulation analyzed the capability of an O-ring gasket to seal a vacuum chamber. The material assignments were given, and the mesh was adjusted accordingly. Supports were given to the groove and a downward displacement was assigned to the top plate. The simulation showed the O-ring deforms such that it conformed to make a full contact on the side walls of the grooved region demonstrating it was adequate in maintaining a seal.

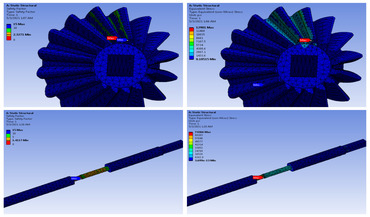

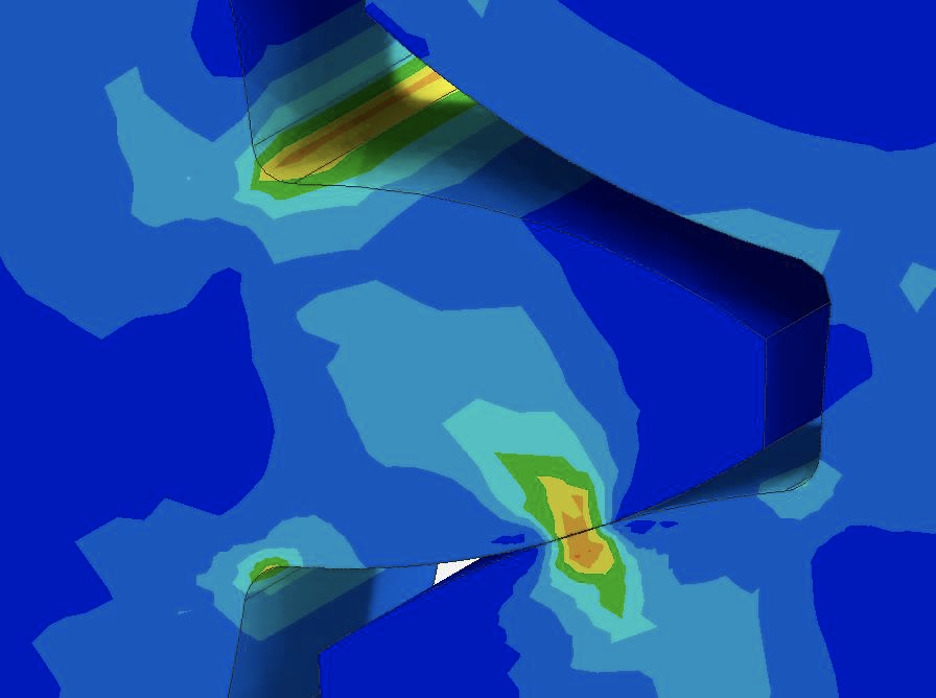

Spur Gear Stress Analysis

This study examined the interaction between a gear and pinion system designed, mated and assembly in SolidWorks and imported to ANYSIS. The gears were given a fine mesh with a concentration on the edges where the teeth make contact for increased stress accuracy. The findings showed the FoS was a mere 0.28 concluding the system needs to be further refined to increase reliability (i.e., enlarging gear size, reducing gear load, stronger gear material).

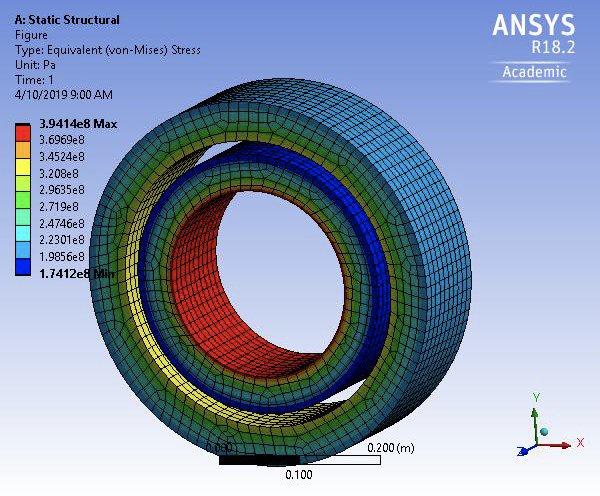

Shrink Fit of Two Cylinders

This simulation aimed to show the tangential stress, deformation and contact pressure for two cylinders under a shrink fit constraint. The process involved creating two separate geometries within each another and defining the contact surfaces of the outer and inner cylinders. A pressure of 30,000 PSI was assigned to the inside surface of the inner cylinder. The largest percent error was under 1.5% percent--showing the accuracy and precision of simulation tools.

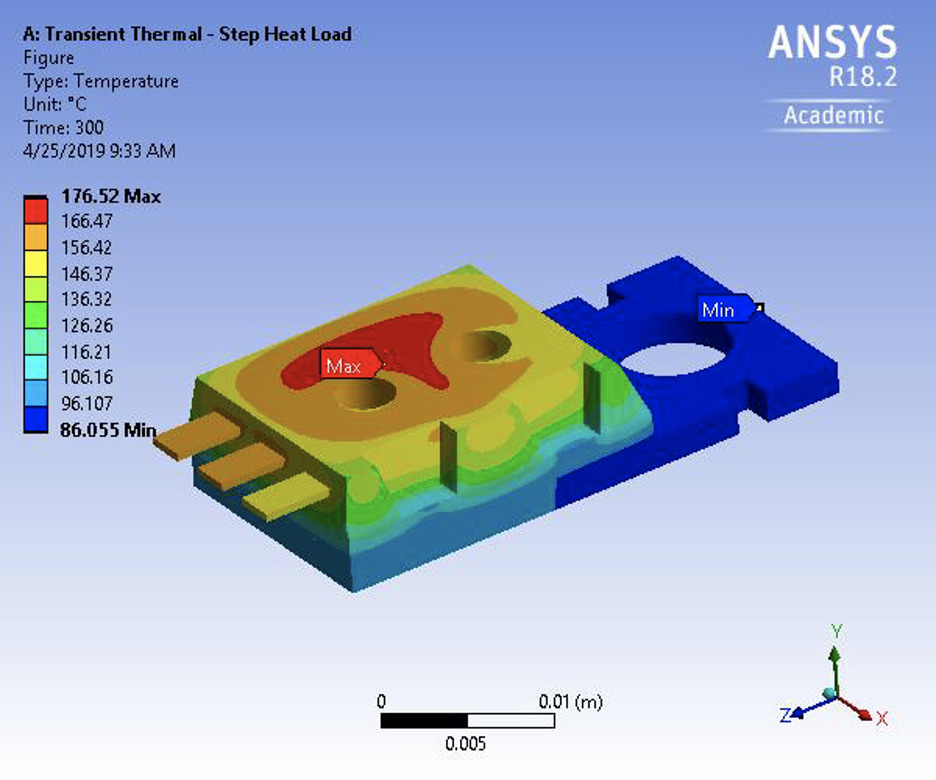

Thermal Analysis of Microchip Assembly

This simulation analyzed temperature exposure on a microchip assembly consisting of a copper base plate and connectors and porcelain. The microchip produced 25 W of heat that dissipated through the assembly then expelled to an ambient air of 25°C. Results showed a maximum temperature of 177°C occurring at the assembly region colored in red and a minimum 86°C at the far end of the base plate. Furthermore, the middle connector had an average temperature of 160°C.

About me

I'm a drafting engineer, specializing in residential design renovations. I graduated with a Bachelor

of Science in Mechanical Engineering from the New Jersey Institute of Technology. While in

school I took part in several internships and gathered industry experience in product development,

product compliance, quality assurance, and website development (I created this site!).

I'm a

skilled communicator having taken on multiple leadership roles in teams of up to 28 individuals from

diverse backgrounds. I have superior analytical and problem-solving skills and the ability to

identify the root cause of issues and implement creative, targeted solutions. I'm

performance-driven

while valuing my mental well-being usually by means of staying fit.

I'm a drafting engineer, specializing in residential design renovations. I graduated with a Bachelor

of Science in Mechanical Engineering from the New Jersey Institute of Technology. While in

school I took part in several internships and gathered industry experience in product development,

product compliance, quality assurance, and website development (I created this site!).

I'm a

skilled communicator having taken on multiple leadership roles in teams of up to 28 individuals from

diverse backgrounds. I have superior analytical and problem-solving skills and the ability to

identify the root cause of issues and implement creative, targeted solutions. I'm

performance-driven

while valuing my mental well-being usually by means of staying fit.

Running has always been my outlet helping me process and reframe many areas of stress

in my life (that's me at the NYC Marathon start line in 2019). When it comes time to unwind, I

like

to sit my feet up and strum my acoustic guitar but even more gratifying to me, is being an uncle to

my two Nieces and two Nephews. Fiona, Kiera, Tristan, and William have vitalized my

life more than I ever would've imagined, and I can't wait to see them grow up. My journey has

not

been easy balancing school and work, but it truly has been rewarding as I have learned many valuable

lessons along the way.

Running has always been my outlet helping me process and reframe many areas of stress

in my life (that's me at the NYC Marathon start line in 2019). When it comes time to unwind, I

like

to sit my feet up and strum my acoustic guitar but even more gratifying to me, is being an uncle to

my two Nieces and two Nephews. Fiona, Kiera, Tristan, and William have vitalized my

life more than I ever would've imagined, and I can't wait to see them grow up. My journey has

not

been easy balancing school and work, but it truly has been rewarding as I have learned many valuable

lessons along the way.

Message me

I am always open to new opportunities and collaborations. If you have a project or idea that you think we could work on together, don't hesitate to reach out to me. I would love to hear from you.